Composite LPG Gas Cylinder automatic turntable line, with its high integration, flexibility and adjustability, high efficiency and high precision, real-time monitoring and data analysis, as well as automatic control and optimization and other technical characteristics, automatic production lines show significant functional advantages in improving production efficiency, ensuring product quality, reducing labor costs and improving production safety

Related Tags

| Machinery Capacity | 300000 pieces per year |

| Weight | 10000 KG |

| Automatic Grade | Automatic |

| Key Machines | Gas Cylinder AutomaticWinding Machine |

| Condition | New |

| Brand Name | Haikong |

| Place of Origin | Shandong, China |

| Voltage | 380V~420V |

| Power | 350KW |

| Winding station | 10 |

| Winding time of a single cylinder | 120s |

| Automatic yarn feeding and cutting | Accept |

| Automatic glue supply | Accept |

| Yarn breakage detection | Accept |

Highly integrated : Composite LPG Gas Cylinder automatic turntable line, each unit module is seamlessly connected through the digital information system to realize real-time sharing and processing of production data

Flexible production : Composite LPG Gas Cylinder automatic turntable line has the ability of flexible processing of small batches and various varieties, which can flexibly respond to changes in market demand.

Automation control : Composite LPG Gas Cylinder automatic turntable line adopts advanced automation control technology to realize automatic control and optimization of the production process

Intelligent management : The information management system of the automatic production line of composite lpg products can realize real-time monitoring and analysis of production data and provide strong support for production decision-making

High precision and high efficiency : Fully automatic production lines for composite lpg products improve product accuracy and consistency while achieving efficient production by precisely controlling the parameters and operations of each link

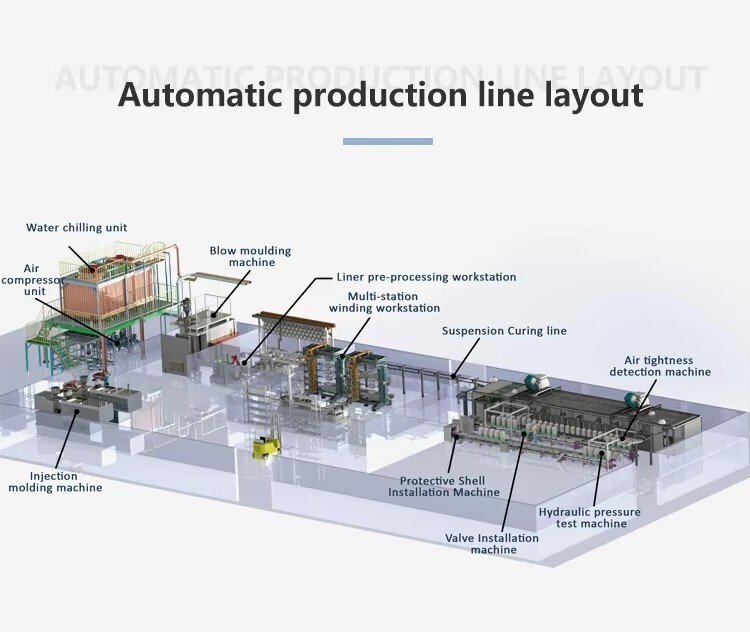

| Automatic intelligent manufacturing production line process flow | |

| step | Manufacturing Process |

| 1 | Blow molding of inner HDPE Liner |

| 2 | Cooling |

| 3 | Liner surface treatment |

| 4 | Winding |

| 5 | Curing |

| 6 | Air tightness/water pressure test |

| 7 | Valve installation |

| 8 | Injection Molding of outer Protective casing |

| 9 | Central control system |

| A、The annual output of this production line is 300,000 pieces,it runs 20 hours a day; B、Total electric power 350KW; C、Production area 2000 ㎡(Storage space is not included),plant height ≥ 7M, equipment inlet width ≥ 5M,equipment entry height ≥ 5M. | |

Training services

Installation and debugging services

Technical Literature Service

Supply services