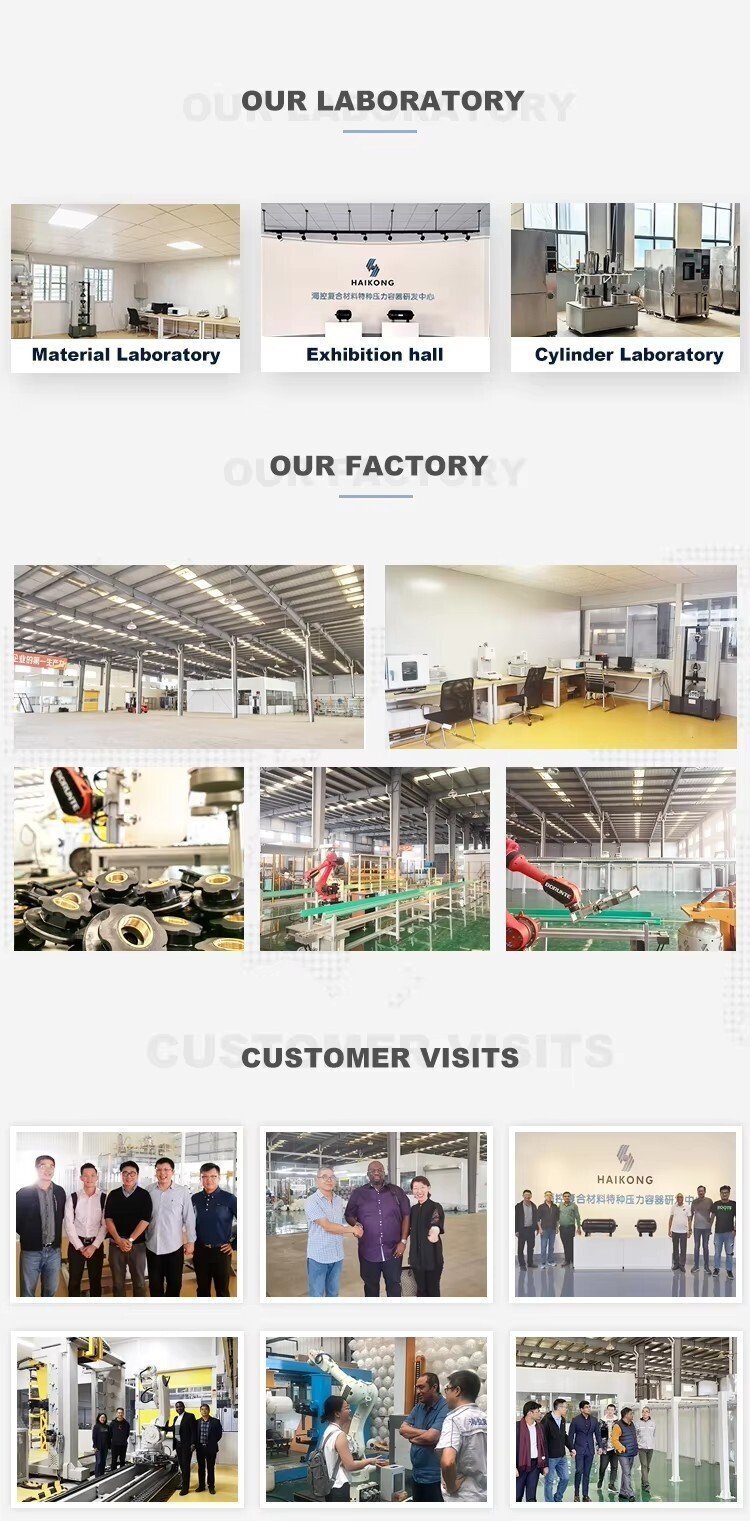

High-quality glass fiber and high-density polyethylene are widely used in the factories that manufacture indian composite cylinder. Our cylinders are developed and manufactured according to national and international standards.

When comparing the glass fiber-wrapped liquefied petroleum gas cylinders with traditional metal steel cylinders, the 26.2L composite material cylinder's appearance design and used materials will be lighter than the traditional steel cylinder......

Related Tags

| Material | Composite Glass Fiber Material |

| Filling medium | Liquefied Petroleum Gas |

| Type of packing | PE plastic net |

| Brand Name | Haikong |

| Place of Origin | Shandong, China |

| Model Number | 26.2L |

| Condition | New |

| Pressure | Low |

| Water Capacity | 26.2L |

| Maximum Filling Weight | 11kg |

| Outer Diameter | 305mm |

| Total Length | 628mm |

| Weight Empty(Valve free) | 6.58kg |

| Test Pressure | 3.2Mpa |

| Working Pressure | 2.1Mpa |

| Operating Temperature | -40~60°C |

| Standard | EN14427/ISO11119 |

High-quality glass fiber and high-density polyethylene are widely used in the factories that manufacture liquefied petroleum indian composite cylinder. Our cylinders are developed and manufactured according to national and international standards.

When comparing the glass fiber-wrapped liquefied petroleum gas cylinders with traditional metal steel cylinders, indian composite cylinder appearance design and used materials will be lighter than the traditional steel cylinder, which is 1/2 the weight, making it easier to transport and carry.

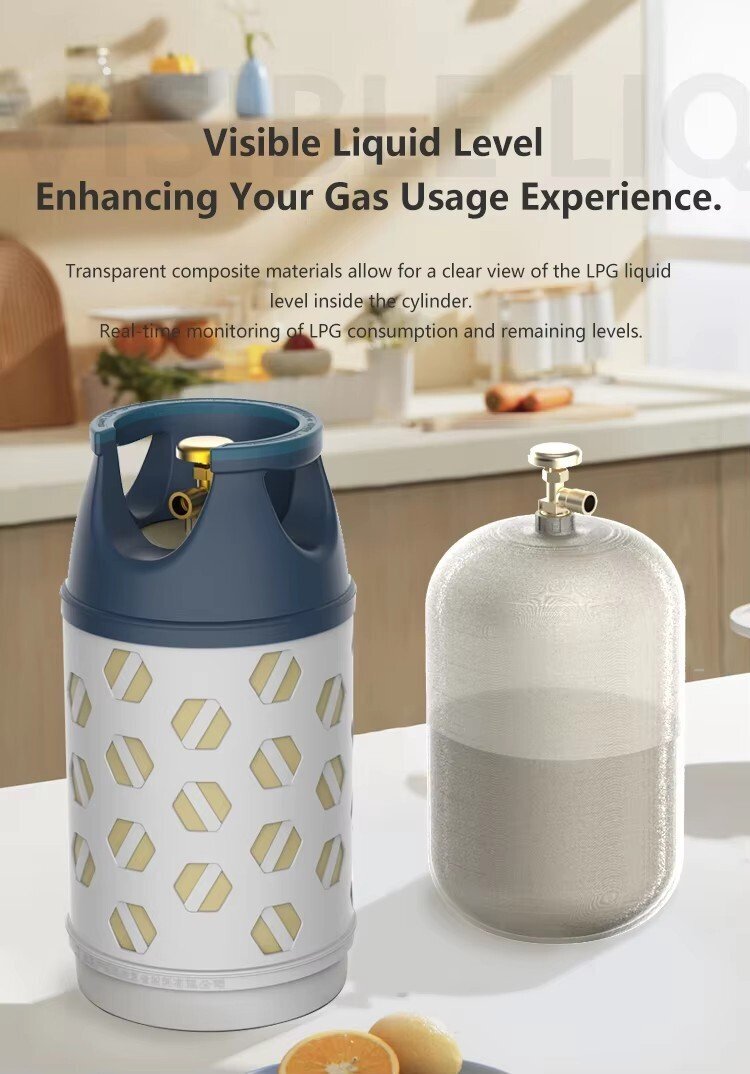

The raw materials used for the 26.2L composite material cylinder can be clearly seen through the transparent composite material, allowing for real-time monitoring of the liquid petroleum gas level and consumption.

indian composite cylinder is suitable for harsh environments.

indian composite cylinder can be used in any environment, including the ocean and humid areas.

Compared to metal cylinders, indian composite cylinder does not need to be regularly rust-proofed or painted during use, and has excellent corrosion resistance.

The potential service life of indian composite cylinder is up to 20 years.

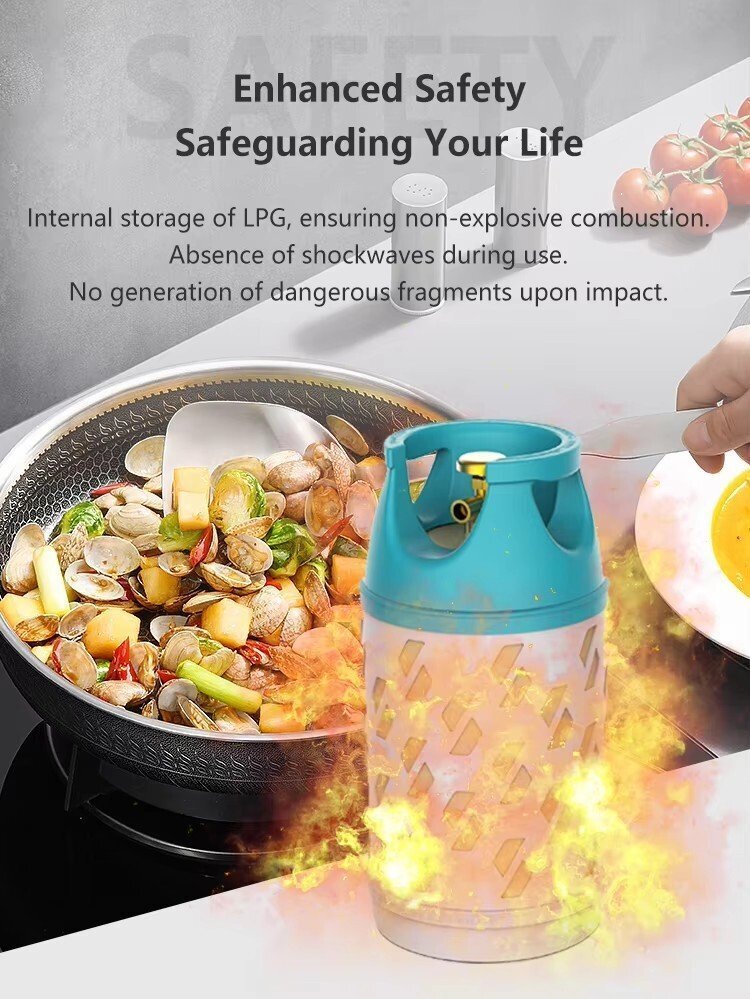

indian composite cylinder is safe, portable, and will not explode, causing injuries to personnel.

indian composite cylinder can be customized according to the customer's preference and requirements.

| SPECIFICATION | 5kg | 7.5 kg | 10 kg | 11 kg | 11.5 kg | 14.5kg | 15kg |

| Water Capacity | 12L | 18L | 24.5L | 26.2L | 27.5L | 34.5L | 35.5L |

| Maximum filling quality | 5kg | 7.5kg | 10kg | 11kg | 11.5kg | 14.5kg | 15kg |

| Outer diameter | 305mm | 305mm | 305mm | 305mm | 305mm | 305mm | 305mm |

| Total Height | 408mm | 508mm | 608mm | 628mm | 655mm | 768mm | 780mm |

| Weight Empty(Valve free) | 4.28kg | 5.25kg | 6.3 kg | 6.58kg | 6.79kg | 7.92kg | 8.1kg |

| Test Pressure | 3.2Mpa | 3.2Mpa | 3.2Mpa | 3.2Mpa | 3.2Mpa | 3.2Mpa | 3.2Mpa |

| Work Pressure | 2.1Mpa | 2.1Mpa | 2.1Mpa | 2.1Mpa | 2.1Mpa | 2.1Mpa | 2.1Mpa |

| Operating Temperature Range | -40~60℃ | -40~60℃ | -40~60℃ | -40~60℃ | -40~60℃ | -40~60℃ | -40~60℃ |

| Approval Standards | EN14427/ISO11119 | EN14427/ISO11119 | EN14427/ISO11119 | EN14427/ISO11119 | EN14427/ISO11119 | EN14427/ISO11119 | EN14427/ISO11119 |

After-sale service

Supply services

Instructions